We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

Michelman products that add value--and support that helps you win—are close at hand, wherever you're growing. Our products enhance the surface qualities of coatings and inks, make composites tougher, and expand the possibilities of paper and film with barrier, functional, and aesthetic features. Our extraordinary technical support helps ensure those products deliver all they can to your bottom line. Micronized Pe Wax Manfacturer

Michelman is a global manufacturer of performance-enhancing barrier, functional, and decorative coatings for flexible film packaging, paperboard, and corrugated boxes; and additives and modifiers for many industries including coatings, inks, composites, and construction products.

Through the centuries wood has been one of the most popular building materials. Good strength, structural properties and relative abundance have made it favored for interior and exterior construction. Coatings have also been used for hundreds of years to improve the durability and to enhance wood's natural beauty.

This short paper will begin by addressing the issues surrounding exterior wood as it ages with special attention to the effects of water and the use of wax emulsions to combat these issues. Discussion also addresses the benefit of wax emulsions and the criteria used to choose the best wax emulsion for the task. Finally a discussion will be presented regarding the evaluation of various wax additives to improve the performance of OEM wood coatings for interior applications.

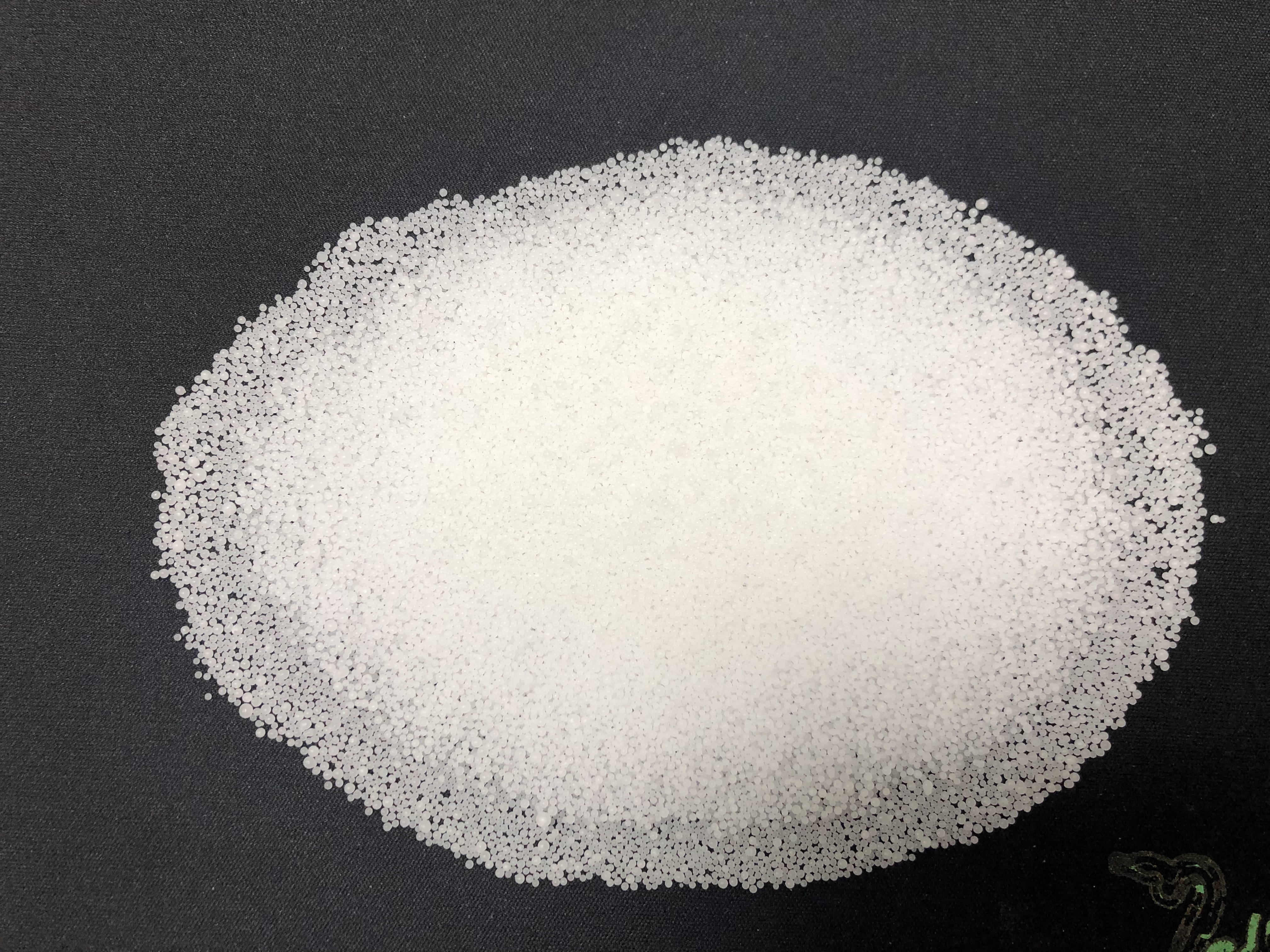

In general waxes are solid at 20°C, varying from soft/plastic to brittle/hard. Melted waxes have relatively low viscosity slightly above the melting point and they flow easily. They can be amorphous or course to fine in crystallinity exhibiting low thermal and electrical conductivity.

Waxes are versatile formulating tools. They have the ability to be dispersed in a variety of medium at almost any particle size. Polar solvents, nonpolar solvents and water can all be used to disperse waxes. Particle sizes can range from tens of nanometers, to micron sized particles to coarse particles.

Additive emulsions of wax modify the coating surface to repel water in water-based wood coatings. Wax emulsions are a uniform dispersion of wax in water for ease of incorporation. Due to its difference in chemical bonding, wax is an inherent water repellent. One of the most important wax properties in protecting wood is this inherent hydrophobicity. Straight-chain hydrocarbon waxes, such as paraffin are quite hydrophobic. These versatile and effective aqueous based wax emulsions can be formulated to have the following properties:

There are two main mechanisms of wax effectiveness:

Figure 1. Increasing heat can cause wax particles to flow and migrate to the surface where they can form a thin film.ace where they can form a thin film.

Formulators of exterior wood coatings face a number of weather induced phenomena (See Figs 2-6). Some of the most common weathering issues include:

Formulators work to increase the durability of exterior wood coatings - Their goals include:

We can compare the effects of using a wax emulsion by adding a small amount to a generic exterior wood coating formula.

Coating A - no wax

Polymer latex, alkyd, oil 60-85%

Polymer latex, alkyd, oil 50-75%

Other additives - pigments, dyes, fillers

Other additives - pigments, dyes, fillers

A small amount of wax (2%) leads to significant improvement to water bead/resistance with little or no impact on raw material cost, while improving water repellency.

While wax in itself does not inhibit UV degradation, it is relatively inert and is not greatly affected by UV light. Many formulators will observe a coating containing wax emulsions to appear to degrade under high UV conditions. Generally it is the interface between wax and the polymer or the stabilizing surfactant.

The water resistance provided by wax emulsions can slow mold and mildew growth, even though waxes are not fungicides. Waxes are not a food source for bacterial growth though some surfactants may be. This is one reason some of best water repellant emulsions contain low surfactant levels. The presence of the water repellant lowers the opportunity for water loving molds and mildews to gain a foothold on the wood. They can also aid the fungicides present by lowering the attack on them by water.

Figure 7. Good versus bad waterbeading

The water repellency improvements in wood coatings can be measured in a number of ways. Among the most common are:

Five wax emulsions in two classes were evaluated using the described methods:

One of the most common and easily identifiable indicators of water repellency is water beading. Water bead is generally easy to observe subjectively without rigorous test procedures (See Fig. 7). However, the most common measurement mechanism for water beading is contact angle - the angle between the substrates surface beneath the bead and the side of bead (Fig. 8).

Figure 8. Illustration of Contact Angle.

Water beading is characterized by wax blooming to the surface. Water beading provides favorable aesthetics to wood, reducing grain raising and usually enhancing actual water resistance with paraffin wax emulsions. Water beading is evidence of water exclusion which can contribute to improved durability (See Fig 9-12).

Figure 9-12 Two minute time sequence showing water beading of uncoated, coated and coated w/wax.

As can be seen the contact angle increases using an acrylic coating and increased even more with a wax emulsion (See Fig. 13-15). The key parameters in testing contact angle include using a smooth pine board. The control is a typical acrylic wood coating without a wax emulsion additive. In this test we evaluated 5 wax emulsions at 3 different loadings (2%, 5% and 10% addition).

Figure 13-15. Contact angles: for Uncoated wood , Coated wood, Coating with wax

A blank of uncoated wood was also used. The samples were placed under accelerated Xenon Arc exposure according to ASTM D2921 (See Figs 16 and 17).

Figure 16. Degrees of waterbead in Xenon Arc weathered wood with and without wax emulsion.

Figure 17. Waterbead - Xenon arc exposure

To achieve excellent water beading we have found a small particle size paraffin/polyolefin blend emulsion with a volatile emulsifier (Michem®Emulsion 62330) and a higher paraffin ratio polyolefin blend with a fixed alkali system to be highly effective (Michem®Lube 368). Increasing the amount of wax emulsion not only improved the initial water beading, but also lengthened its span of effectiveness (See Fig. 18).

Figure 18. Waterbead at various amounts of wax emulsion under Xenon arc exposure

Optimal resistance to water penetration in wood coatings is often the result of a synergy between the waxes used in a co-emulsion of a straight chain hydrocarbon paraffin wax and a polymeric material. These wax blend emulsions can pass ASTM D-4446 for swell resistance. They are also very effective in passing ASTM D-5401 test for water absorption.

Water resistance includes all the characteristics described above for water beading as well as several additional attributes:

To determine the effectiveness of the tested samples for water resistance a qualitative evaluation of coating appearance with/without wax emulsion is carried out by exposing the coated board to Xenon Arc lighting. The samples were exposed to the same accelerated Xenon Arc exposure. The samples were evaluated on a scale of 0 (extreme damage) to 5 (no damage) (See Fig 19).

Figure 19. Appearance of Xenon arc exposure.

One of the most effective quantitative measurements of water resistance in wood coatings is resistance to swell. Swell resistance as defined by ASTM D-4446 is the measurement of swell of coated wood compared to uncoated wood after water submersion. Passing is 60% efficiency. In the continuation of testing for water resistance an initial appraisal of the quality of the wood sample is necessary. The same experimental set up is carried out as was done when evaluating water contact angle.

The test included a control, blank and five additives at three different levels. At least 60% water repellency efficiency (WRE) compared to uncoated is required to pass the ASTM D-4446 test. The test was carried out using Ponderosa Pine wood. A polymer wax co-emulsion was added to the test evaluation (Michem®Wood Coating 70 low VOC) (See Figs 20-23).

The calculation for percent efficiency is as follows:

The paraffin/polymer co-emulsion can be very effective in providing dimensional stability, sometimes reaching over 80% efficiency in resisting swell (See Figs. 24-25).

The gravimetric test determines the amount of water absorbed, in coated pine versus uncoated over a 3 months outdoor exposure under ASTM D-5401. As can be seen the acrylic coating with a wax emulsion show improvement while the use of the paraffin polymer blend is even more effective (See Figs. 26 and 27).

Many governments continue to implement regulations aimed at reducing VOC's in exterior coatings. Wax emulsions can be used to reduce VOC. In the United States many wood water-proofer, stain and finish formulations were regulated in 2007 to a level of less than 100 grams/liter VOC. In general wax emulsion are very low in VOC content. When used in wood coating formulations wax emulsion additives must retain stability in a variety of systems despite reduction in volatile organics. Non-VOC coalescing aids may be required to ensure stability - does not affect performance: Two products which show exceptionally low VOC's and excellent stability are the fine particle size paraffin/polyolefin blend with volatile emulsifier system (Michem®Emulsion 62330) and the low VOC water resistant paraffin/polymer co-emulsion (Michem®Wood Coating 70 Low VOC). (See Table 1).

Table 1. % VOC's by weight of various wax emulsions.

Paraffin/polyolefin (high paraffin ratio) blend with fixed alkali anionic emulsifier system (Michem®Lube 368)

Paraffin/polyolefin (lower paraffin ratio) blend with fixed alkali anionic emulsifier system (Michem®Lube 270R)

Small particle size paraffin/polyolefin blend with volatile alkali emulsifier system (Michem®Emulsion 62330)

Nonionic paraffin emulsion (Michem®Lube 743)

Paraffin/polymer blend co-emulsion (Low VOC) (Michem®Wood Coating 70LV)

As low as 2% wax emulsion additive addition can lead to a significant improvement in waterbeading. The phenomena of wax bloom and relatively low raw materials cost enhances the value of the using a small amount of wax emulsion. Higher loadings can contribute to enhanced performance as defined by water resistance and durability

The evolution of wood coating binder systems has altered the compatibility and performance of additive packages. The purpose of this study is to evaluate the influence of various aqueous wax emulsions in a water based varnish for interior wood (furniture) with the objective of maximizing:

A wood varnish without wax served as the base formula for our tests of wax emulsions. An air spray gun was used to coat the wood to replicate the method used in industry. Roughly 20 wax emulsions and dispersions were screened for compatibility using 6 different styrenated acrylic resins. Based on the results 16 emulsions were subject to further evaluation, for various performance characteristics in a standard acrylic copolymer wood coating formulation. Some of the most compatible wax emulsions vs the 6 screening polymers have been tested in a clear spray varnish and performance compared to a wax-free formulation (See Table 2).

Table 2. Standard Wood Finish formulation

wax 4% solids on total formulation

The thickener level was adjusted to achieve desired viscosity. Ingredients were added in listed order and mixed by dissolver for. 20 minutes. Results are provided from testing 4 diverse waxes.

Samples were prepared by spraying a 150µ wet coating on pine wood with spray gun. Drying 24h at room temperature (RT)

Description of the test methods used:

Wax emulsions, wax co-emulsions and wax dispersions when used at 3% to 5% provides the following properties in wood coatings:

Michelman testing indicated key improvements in compatibility, scratch resistance, lubricity, and gloss retention after abrasion with small particle size paraffin polyethylene co-emulsions, larger emulsion particle Fischer Tropsch emulsion. The Montan micronized dispersion also performed well (See Table 3).

Table 3. Summary of interior wood coating wax emulsion.

Small particle paraffin /poly blend

Most water beading paraffin and paraffin/polyolefin wax emulsion are added at typical usage levels of 2 to 10 %. (Michem® Emulsion and Michem® Lube). Typical usage of the more water resistant paraffin/polymer coemulsions is 5 to 30% of total solids. (Michem® Wood Coating series).

Wax emulsion additives enhance the durability of aqueous exterior wood coatings by:

In summary, when formulating for water resistance in exterior wood coatings and selecting the appropriate water repellant additive you will need to account for:

In addition to water repellency wax emulsions, as demonstrated in the interior wood varnish formulation can provide the following benefits :

This information has been sourced, reviewed and adapted from materials provided by Michelman.

For more information on this source, please visit Michelman.

Please use one of the following formats to cite this article in your essay, paper or report:

Michelman Inc. (2020, May 06). Modifying the Effects of Water on Aqueous-Based Coatings and Enhancing Secondary Properties in OEM Wood Coatings. AZoM. Retrieved on October 11, 2023 from https://www.azom.com/article.aspx?ArticleID=4906.

Michelman Inc. "Modifying the Effects of Water on Aqueous-Based Coatings and Enhancing Secondary Properties in OEM Wood Coatings". AZoM. 11 October 2023. <https://www.azom.com/article.aspx?ArticleID=4906>.

Michelman Inc. "Modifying the Effects of Water on Aqueous-Based Coatings and Enhancing Secondary Properties in OEM Wood Coatings". AZoM. https://www.azom.com/article.aspx?ArticleID=4906. (accessed October 11, 2023).

Michelman Inc. 2020. Modifying the Effects of Water on Aqueous-Based Coatings and Enhancing Secondary Properties in OEM Wood Coatings. AZoM, viewed 11 October 2023, https://www.azom.com/article.aspx?ArticleID=4906.

Do you have a question you'd like to ask regarding this article?

AZoM.com - An AZoNetwork Site

Low Melting Pe Wax Owned and operated by AZoNetwork, © 2000-2023